Lätta kompositer är starka och slitstarka material med låg vikt. Sådana kompositer skapas genom att blanda två olika material för att få en slutprodukt med de båda materialens bästa egenskaper. Lätta kompositer kan erhållas genom peroxidoptimerad härdning. Peroxidhärdning är en process där två eller flera material kombineras med hjälp av en kemisk förening kallad peroxid, vilket möjliggör bindningsbildning och säkerställer en hårt sammanfogad komposit med hög styrka. Genom denna processtekniska optimering kan tillverkaren producera kompositer som inte bara är lätta, utan också visar bättre prestanda jämfört med traditionella material

Lätta kompositer för överlägsen prestanda

Optimering av peroxidhärdning kan leda till lättviktskompositer, överlägsna för en mängd olika tillämpningar. Till exempel kan de lättare kompositerna användas i bilar för att göra dem mer bränsleeffektiva och miljövänliga. När du minskar vikten på en bil totalt kan du förbättra dess bränsleförbrukning och minska mängden skadliga utsläpp den släpper ut. Slutligen kan även flygplan använda lättviktskompositer så att planen blir lättare och mer bränsleeffektiva. Dessa kompositer kan i sin tur sänka det totala vikten på ett flygplan, vilket gör att det kan färdas längre sträckor med mindre bränsle. Generellt sett kan lättviktskompositer med optimerad peroxidhärdning erbjuda förbättrade prestandafördelar inom många sektorer

Engångsalternativ för kostnadseffektiva lösningar

Anläggningen i San Diego, öppnad 2016 bara ett dussin miles från gränsen mot Mexiko, tillverkar tryck- och temperaturmätare för nedförborrning till olje- och gassektorn med hjälp av lättviktskompositer bearbetade under optimala förhållanden peroxid härdning som sedan tillverkas i stora mängder för grossistmöjligheter. Dessa kompositer kan tillverkas i stora kvantiteter av tillverkare, potentiellt för att minska den totala produktionskostnaden. Att köpa lättviktiga kompositer i storformat kan spara material och produktionskostnader. Vanligtvis gör en sådan ekonomisk strategi att företag kan bibehålla konkurrenskraft inom sina marknadssegment även när de levererar hög kvalitet. Storleversans av lättviktskompositer kan också hjälpa företag att möta ökad marknadsefterfrågan på hållbara och miljövänliga material. Att göra kostnadseffektiva investeringar i lättviktskompositer innebär att företag är väl positionerade att växa tillsammans med marknaden snarare än att hamna efter

Så får du bästa resultat med peroxidhärdning

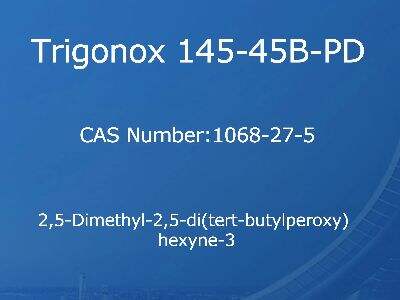

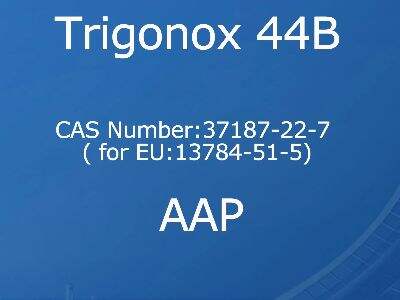

På Thousands Chemicals utformar vi lättviktskompositer genom peroxidhärdning med optimerad process. Peroxidhärdning är en härdningsmetod som innebär användning av ett peroxid kemikalier som orsakar en reaktion som hårdnar kompositer. För att maximera effektiviteten av peroxidhärdning är det viktigt att noggrant hantera härdningsprocessen. Allt som bör beaktas inkluderar typen av peroxid, rätt temperatur och härdningstid för din specifika situation samt tillräcklig ventilation så att biprodukter kan avgå under härdningen. Genom dessa åtgärder kan företag utveckla lättviktiga, men ändå starka, slitstarka och högpresterande kompositer

Vanliga frågor om produkter

Det finns ett antal användningsproblem som användare måste hantera vid peroxidhärdning. Till exempel kan otillräcklig peroxidblandning leda till icke-uniform härdning och sämre kompositer. Dessutom kan felaktig peroxidtyp och otillräckliga härdningsfaktorer leda till dåliga resultat. Här på Thousands Chemicals har vi utvecklat produkter som är skräddarsydda för att lösa dessa vardagliga utmaningar. Våra peroxider är konstruerade för att leverera pålitliga härdhastigheter, och vårt tekniska team står redo att ge stöd i hur du bäst använder våra produkter. Med Thousands Chemicals vet företag att deras peroxider kommer att prestera, oavsett omständighet

Hur man väljer rätt peroxidhärdningstekniker

Det rätta valet av peroxid härdningsmetod är avgörande för att tillverka lättviktskompositer med den styrka och prestanda som krävs. Typ av kompositmaterial (PMMA/PEEK), den nödvändiga härdningstemperaturen samt tiden för efterhärdning måste beaktas. Vi levererar ett brett utbud av peroxider speciellt utformade för olika härdningsmetoder, så att tillverkare enkelt kan välja rätt produkt för sina unika applikationer. Vårt tekniska team kan erbjuda stöd vid valet av optimal peroxidhärdningsprocess för era behov, vilket krävs för att uppnå kundnöjdhet via en snabb och ekonomisk process. Med tusentals kemikalier kan de vara säkra på att de använder rätt peroxidhärdningsprocess för att skapa lättviktskompositer som är starka och slitstarka – även vid höga temperaturer

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

HY

HY

AZ

AZ

KA

KA

LO

LO

MN

MN

MY

MY

KK

KK

SU

SU

TG

TG

UZ

UZ