Isophthalinsäureharz ist ein einzigartiges, unglaublich vielseitiges Material, das von verschiedenen Branchen genutzt wird, weil es große Stärke und Zähigkeit aufweist. Nachdem das Harz hart geworden ist, werden Thermosätze nicht mehr remelzen und bilden daher haltbare Produkte wie Bootsrümpfe, Chemietanks oder Windturbinenflügel. Auch seine Widerstandsfähigkeit gegen Wasser und UV-Stabilität macht es ideal für den Außeneinsatz. Isophthalinsäureharz: Neben den bereits genannten Gründen sind Isophthalinsäureharze kosteneffektiv – Sie können sie zu günstigen Preisen erwerben.

Die hervorragende Verträglichkeit mit einer Vielzahl von Fasern und Verstärkungsmaterialien, von Glas bis zu Polyester-Substraten, sind nur einige der zusätzlichen Vorteile, die das Isophthalinsäureharz noch attraktiver machen. Dies kann mit einer Vielzahl von Fasern kombiniert werden, einschließlich Glasfaser, Kohle, Aramid Kevlar, Hanf und Leinen oder als Kernmaterialien wie Schaumkern, Balsaholz Waben. Diese Flexibilität ermöglicht es Herstellern, den Gehalt entsprechend ihren genauen Anforderungen anzupassen, wodurch es sehr gut für Serienproduktion geeignet ist.

Die Arbeit mit Isoharz kann gefährlich sein, da der Gebrauch einer Atemmaske oder einer angemessenen Belüftung sehr wichtig ist, um eine Vergiftung durch das Einatmen der Dämpfe dieses Produkts zu vermeiden. Angemessene Belüftung, persönliche Schutzkleidung (einschließlich Handschuhen und einem Atemschutzgerät) sowie 100%ige Einhaltung der Herstelleranweisungen sind für eine sichere Handhabung und Verwendung unerlässlich.

Isophthalic-Harz hat vielfältige Anwendungen in verschiedenen Industrien. Seine Verwendung ist im Automobilbereich weit verbreitet für tragende Komponenten wie Kotflügel und Karosserieelemente. Der Schifffahrtsektor verwendet es für Bootsrümpfe, Decks und Inneneinrichtungen sowie die Baubranche in Trägern und Säulen. Weitere Anwendungen von Isophthalic-Harz sind in den elektrischen und Windenergie-Sektoren für eine Vielzahl von Komponenten. Es ist so vielseitig und widerstandsfähig, dass es für viele Artikel verwendet wird.

Während viele der durch Isophthalic-Harz verliehenen Vorteile schon länger bekannt sind, hat seine Produktion und Verwendung auch umwelttechnische Herausforderungen bereitet, da es nicht biologisch abbaufähig ist. Obwohl es nicht giftig ist, stellt die begrenzte Recycelbarkeit Fragen bezüglich dessen, was geschieht, wenn wir Millionen dieser Autos haben. Es werden auch Bemühungen unternommen, Recyclingmethoden zu untersuchen und grünere Alternativen zu schaffen, damit es weniger schädlich für die Umwelt ist.

Zusammengefasst sind Isophthalinsäureharze ein haltbares und vielseitiges, kostengünstiges Material für verschiedene industrielle Anwendungen. Während Vorsicht geboten ist, um es auf sichere Weise zu verwalten, wird auch an diesem Problem gearbeitet, um nicht nur die Umweltauswirkungen zu verstehen, sondern auch nachhaltige Alternativen für die Zukunft zu finden.

Hohe Verkaufszahlen werden durch ein professionelles Service-System unterstützt, das technische Hilfe bei Isophthalsäureharz umfasst, einschließlich der Formulierungsplanung, Materialauswahl für Projekte, sowie After-Sales-Services.

Tausende von Unternehmen mit Isophthalsäureharz betreiben weltweit Geschäfte über lizenzierte Marken. Wir garantieren die Echtheit jedes Produkts und verfolgen die Markenphilosophie konsequent.

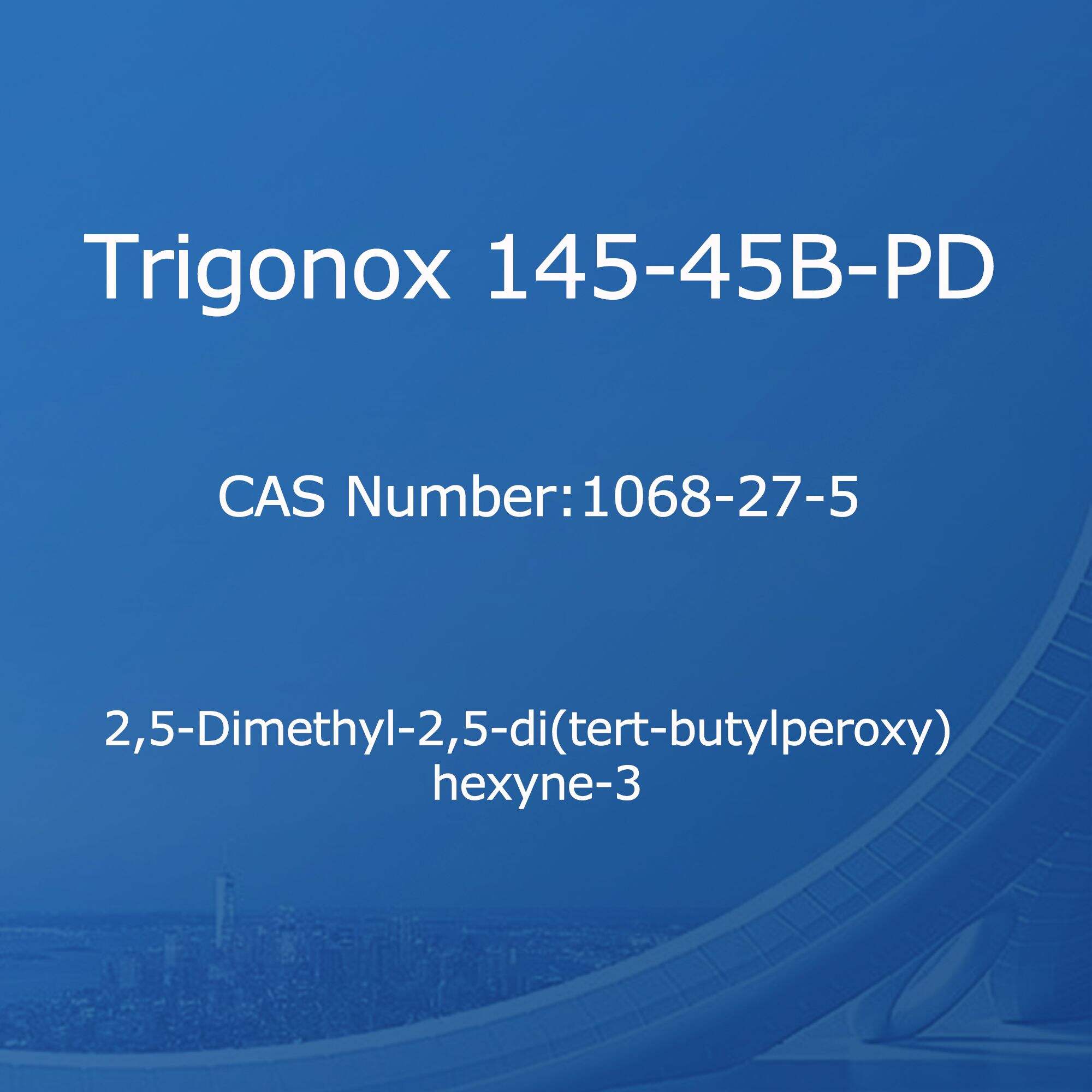

Wir verfügen über fundierte Kenntnisse im Bereich Isophthalsäureharz und internationale Standards für gefährliche Chemikalien; wir exportieren gefährliche Güter der Klasse 5.2, einschließlich temperaturgeführter Artikel.

Wir sind Spezialisten im Einsatz von Composite-Isophthalsäureharzen sowie in vielfältigen Produktionsverfahren, was es uns ermöglicht, unsere Kunden zu beraten und ihnen dabei zu helfen, optimale Ergebnisse aus ihren Produkten zu erzielen.