It is a substance that prevents the adherence of the molded parts to the molds in which they are made. Think about when you bake a cake and grease the pan with oil or butter. Shaking the cake pan with a little force will help in getting the cake out without breaking. The same applies to mold release agents. They help when removing the molded parts when they are done. There are three main types of mould release agents: chemical, physical and natural.

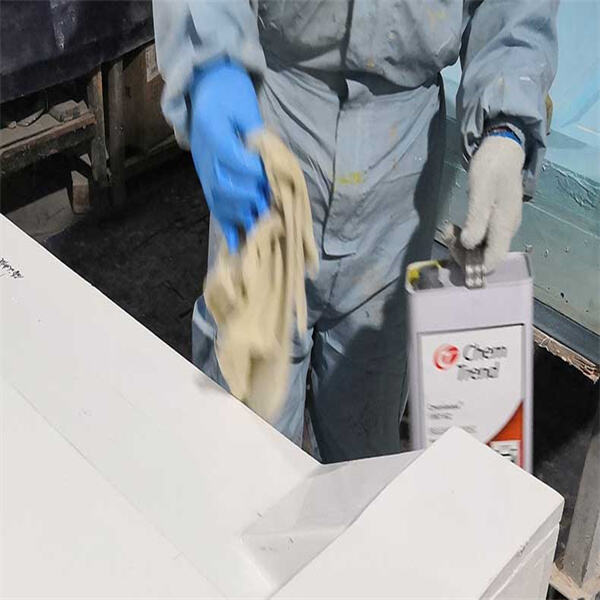

It is very important to use the mold release agents for ensuring the quality of the parts. When molded parts adhere excessively to the molds, they risk breaking or getting damaged during extraction. When it happens, it creates issues for the manufacturers because they want to make stiff and perfect components. Mold release agents also help the parts safely exit the mold, so they don’t get damaged and remain in good condition. This is essential for maintaining a seamless and efficient production process.

Selecting the proper release agent for your particular task is essential. Different molds and parts work better with different agents. Silicone-based products, for instance, work well for high-temperature applications, such as creating components that are to be used in high-heat locations. Conversely, the use of water-based agents is better suited for low-temperature operations where the parts do not get that hot.

When selecting an agent there are several things to consider. These include what kind of mold you are using, the temperature of the process, and what type of part you are making. Taking the time to find the right agent will allow your parts to come out easily and without issue.

There are good things about eco-friendly mold release agents than usual. The first reason is that most of the time they are safer because they do not release harmful chemicals into the atmosphere which can hurt people and the earth. This is paramount in a world today where being green is highly sensitive.

The second benefit of eco-friendly agents is they help to reduce waste and pollution. That is because they consist of natural materials that decompose in time. These agents help maintain our planet hygienic and secure for generations to come.

Last but not least, green mold release agent can save money too. You also need less of them in many cases than traditional agents, so you can obtain excellent results for less money spent on the materials.